Constrained panel (in an assembly document only) :

Select Constrained panel mode.

Select face.

Select orientation.

Define offsets.

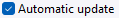

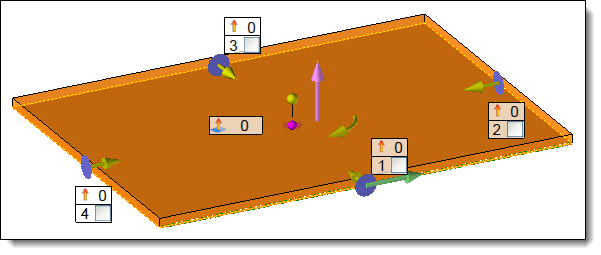

Select panel position relative to face:

|

Panel on profile (in a panel or assembly document) :

Choose or create a profile directly.

Select an orientation.

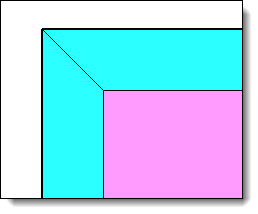

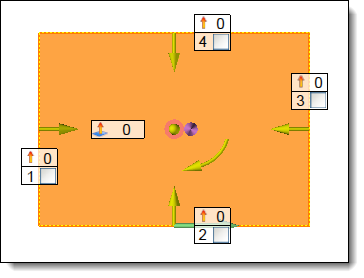

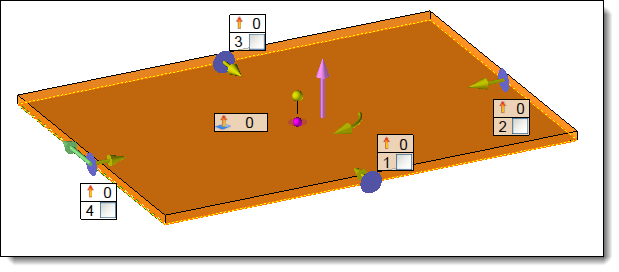

Select the position of the panel in relation to the profile:

|

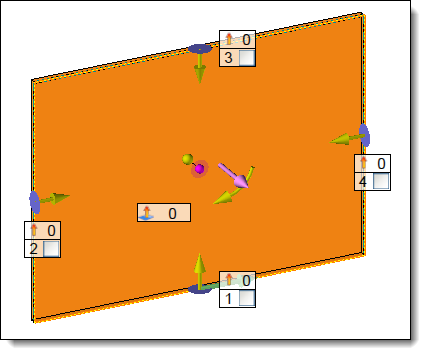

Panel on face (in an assembly document only) :

Select one or more faces. (Select multiple faces to create a panel

panel from several faces)

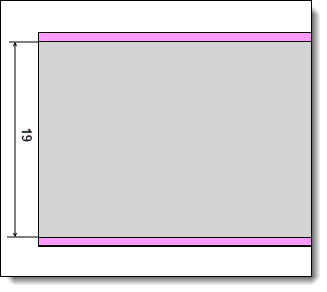

Select an orientation.

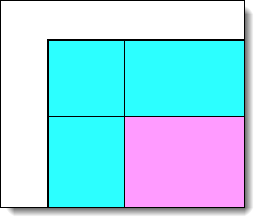

Select the panel position relative to the face:

|