Hale machining

|

Hale machining |

Hale machining is a process used to create fine engravings and specific patterns using the shape of the insert.

This function also offers the possibility of executing a material left operation or finishing work on any type of face to mark the part or adjust its surface quality.

For this type of machining, there is no tool rotation and the part is fixed, only some linear machine axes are in motion to follow the elements to be machined.

This process only requires a feed rate to be specified in the cutting conditions.

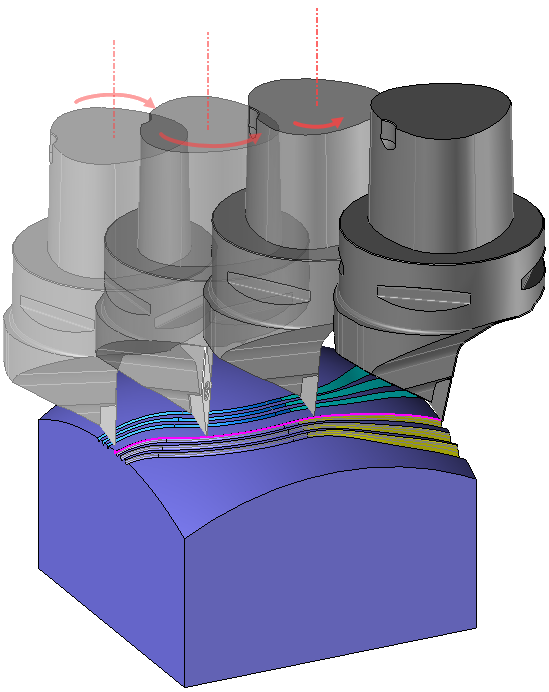

The spindle axis must be programmable to control the orientation of the cutting part of the tool, so that it remains perpendicular to the profile at all points.

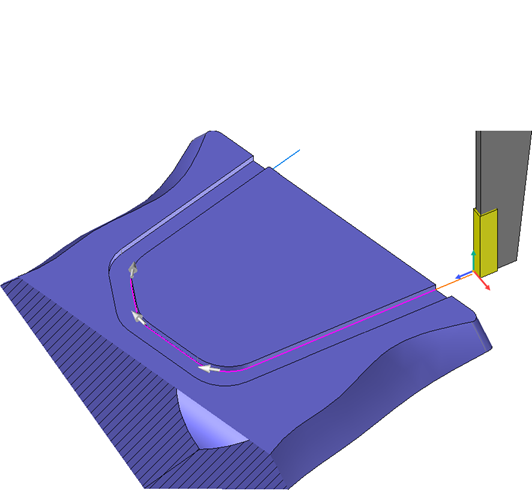

Below is an illustration of tool positioning according to the profile to be machined.

If the machine does not have this kind of axis, or if it is not aligned with the tool pocket, it will not be possible to perform a Hale machining operation.

It is strongly recommended to have a minimum angular range of 360° on the axis supporting the tool.

This operation specifically requires turning tools and can be performed with any insert.

This operation is available in both 2D and 3D.

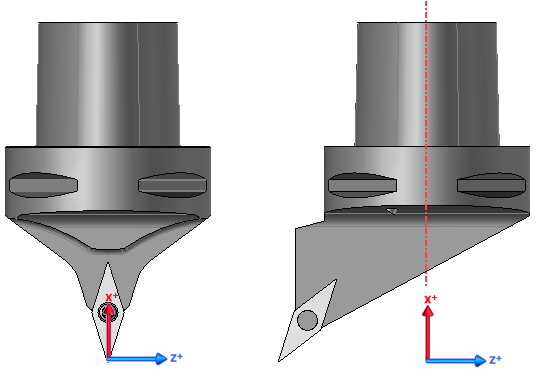

Tools can be driven in 2 different ways:

Either on a tool center as for milling ( assuming the machine has a cycle to support it)

Either directly in relation to the axis of rotation (certainly the only solution if no machine cycle to support it is available). In this case, this point must first be defined in the tool definition (generic turning tools are not suitable here).

![]() You can edit the driven points on the insert.

You can edit the driven points on the insert.

However, automatic mode is not supported when editing the driven point; by default, the driven point used is the one at the center of the insert..

![]()

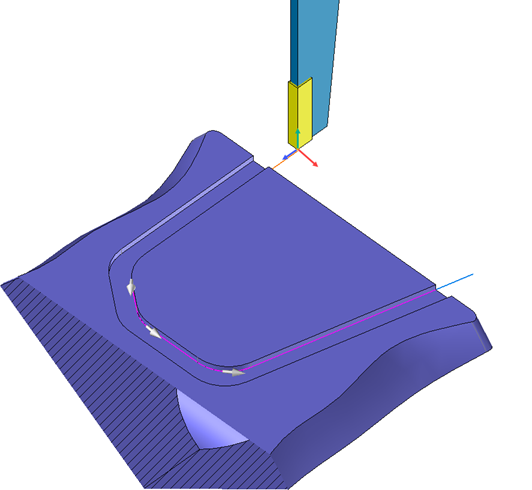

A restriction must be taken into account for turning tools defined as left-hand or right-hand tools (as can be found on generic rectangular groove tools).

These tools can only machine in one direction.In this case, the operation manages only one machining direction, in order to stay on the correct side of the material.

The Hale machining is based on the cutting edge origin position ( located on the right-hand side of the insert for “Right-hand” tools and vice versa for “Left-hand” tools).

a) For tools with the cutting edge origin on the right, the insert is positioned on the left of the profile in the machining direction.

b) For tools with the cutting edge origin on the left, the insert is positioned on the right of the profile in the machining direction.

Case a) The tool is on the left of the profile Case b) The tool is on the right of the profile

![]() Tools with the cutting edge origin placed at the center are not affected by this restriction.

Tools with the cutting edge origin placed at the center are not affected by this restriction.

![]()

The stock update is not managed by the operation.

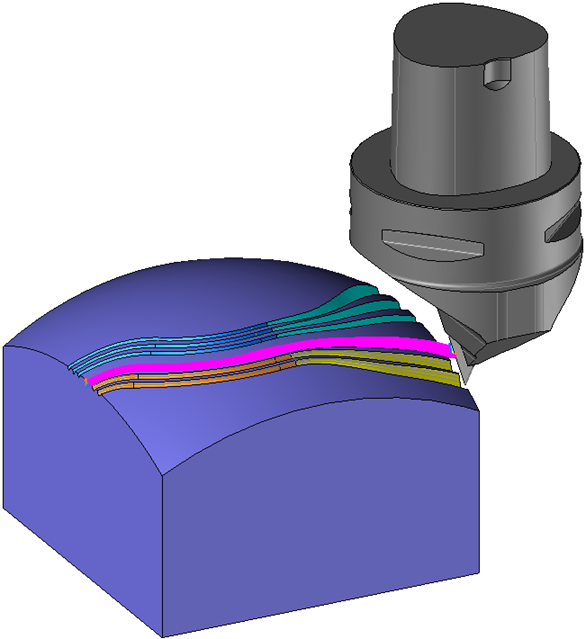

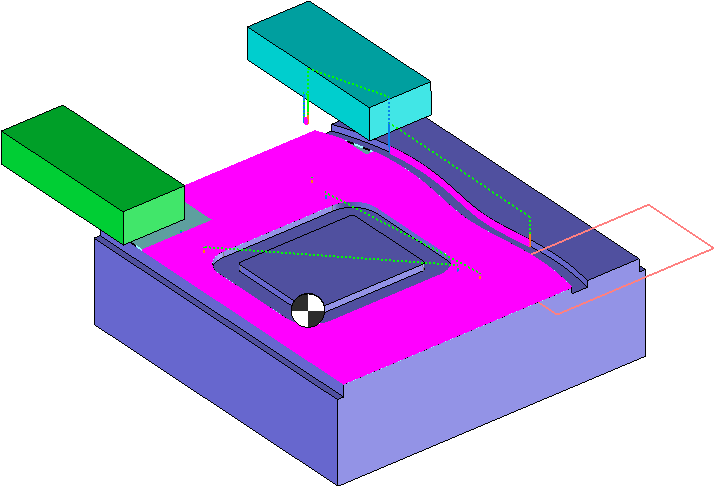

Hale machining is available for Side milling ![]() , 3D Contouring

, 3D Contouring ![]() and some 3D Finishing

and some 3D Finishing  (Raster, Constant step over and Morphing).

(Raster, Constant step over and Morphing).

Tool paths will behave in the same way as when the tool used is a milling tool.

Depending on the type of preliminary operation required, the element to be machined may be a face, profiles or support curves.

Once this choice has been made, go to the 4/5axis menu  and activate the 3X + Hale machning option.

and activate the 3X + Hale machning option.

If a milling tool has already been mounted by default, it is automatically removed; It is necessary to manually mount a suitable tool using the tool manager.

Hale machining then creates the tool paths and authorizes the same processing that applies to the original operation: limitation, path optimization, retract management, etc...

![]() Always check the tool position by specifying the material side or machining direction, as explained above in the specific case of right and left-hand tools.

Always check the tool position by specifying the material side or machining direction, as explained above in the specific case of right and left-hand tools.

![]() As Hale machining is linked to a preliminary operation, it is not possible to change from contouring to finishing during the editing process.

As Hale machining is linked to a preliminary operation, it is not possible to change from contouring to finishing during the editing process.

In this case, it is necessary to cancel the current edition and select the correct preliminary operation.

Whatever the operation, an option specific to Hale machining (and accessible in the tab of the same name) enables you to activate or deactivate the continuous mode.

Enabled by default, the Hale machining axis will rotate to position the insert perpendicular to the machining direction.

If disabled, the tool does not rotate and the Hale machining axis remains in its initial position.