A method document defines a sequence of multiple commands to automate

modeling tasks, resulting in significant time savings for repetitive modeling

processes.

|

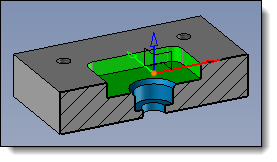

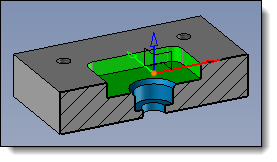

We want

to create a method with the following operations:

To simplify the positioning of these operations, we will use

a constrained frame.

|

|

Create a new part document

containing an arbitrary shape. Place a constrained frame on

its top face - Create a sketch on the XY plane

of this frame, with the origin at the frame's origin and its

Y-axis as the vertical direction.

- Create a parallel profile to this

sketch and declare these 4 segments as construction elements.

- Make a pocket from the inner profile.

- Create a drilling group from the

4 vertices of the parallel profile (with a tapped hole diameter

of d_tapped_hole=8mm).

- Create a spot facing hole from

the constrained frame, using the bottom face of the pocket

as the starting face (with spot facing diameter of d_spot_facing=20mm

and hole diameter d_spot_facing/2).

You also have the option to create machining

processes documents to associate colors with the operations.

Note that the coloring

operation is not managed by the method.

|

|

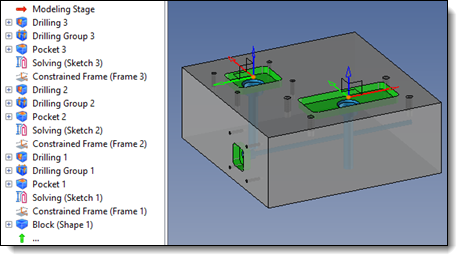

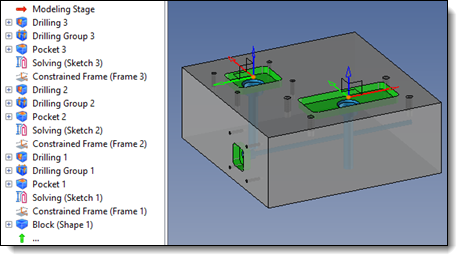

Create a new Method

document and set the part document as the generic

document. From the entities tree, drag

Shape 1 from the Geometric

Generics folder into the Drivers

folder. Also, drag Frame 1 into the

Drivers folder (you

will notice that it is automatically removed from the Operations folder). Drag the parameters d_tapped_hole

and d_spot_facing

from the Generics

folder into the Optional

Drivers folder. By double-clicking on these

drivers, you can add a designation (text that will be displayed

in the dialog when applying the method). Save your method document.

|

|

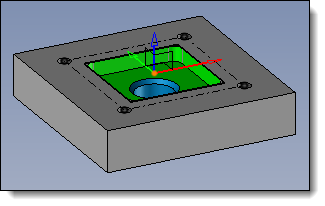

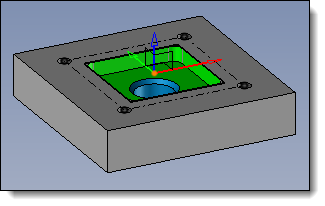

Create a new part document

and create an arbitrary part within it. Drag and drop your method document

or use the Tools > Apply Method

command. - Select the shape and place the

constrained frame dynamically.

- Modify the driver parameter values

if necessary.

- Validate the dialog.

- Repeat the method application

as needed.

We observe that the operations are recreated in the operations

tree. They can be modified at will (for example, to change the

dimensions of the pocket).

Depending on the data entered for the drivers, observe the result

in the Parameters folder

of the feature tree (see the driver management in the  box above). box above).

|

Example of creating and using a method with entity

to basify to exclude it from method operations:

|

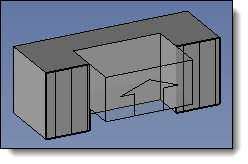

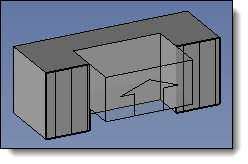

Method

for creating, in an assembly, the housing of one part within another.

|

|

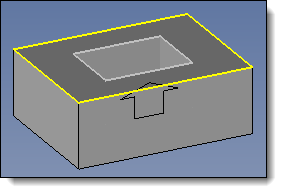

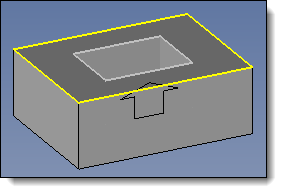

Create a new part assembly

document. Create an arbitrary block envelope. Create a sketch on the top

face of this block envelope (with dimensions larger than the

block envelope). Change its attributes to a

yellow color. Create an in-place part and

extrude the yellow sketch in the Z- direction. Create a sketch on the top

face of the block envelope and project the edges of this face

(gray sketch). Make a trim by profile operation

between the gray sketch and the in-place part.

|

|

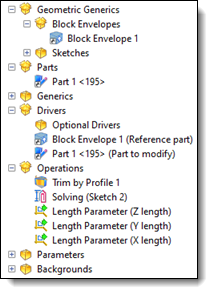

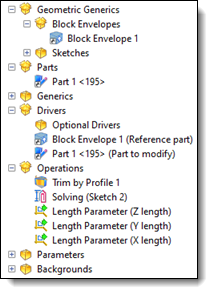

Create a new Method

document and set the assembly document as the generic

document. From the entities tree, drag

the block envelope from the Geometric

Generics folder into the Drivers

folder. To be able to select the part

you want to trim, also drag the part from the Parts

folder into the Drivers

folder.

We can see that the sketch that was

used to create this part remains in the operations folder. Keep

it in this state.

From the entities tree, drag

the block envelope from the Geometric

Generics folder into the Drivers

folder. By double-clicking on these

drivers, you can add a designation (text that will be displayed

in the dialog when applying the method). Save your method document.

|

|

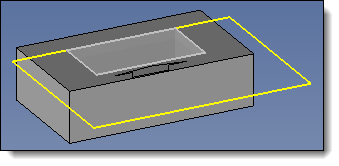

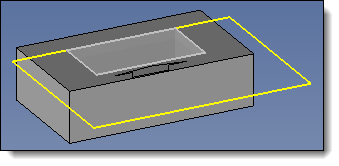

Create a new assembly document

and create 2 parts, one inside the other. Drag and drop your method document

or use the Tools > Apply Method

command. Select the small part as the

driver for the block envelope. Select the large part as the

part to modify. Validate.

The trim has been successfully applied, but the yellow sketch

from the generic part appears because it is constructed on the

block envelope, which is a driver of the method.

It is unnecessary and clutters the assembly.

|

|

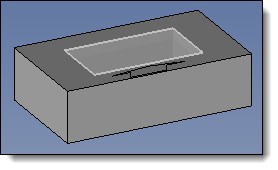

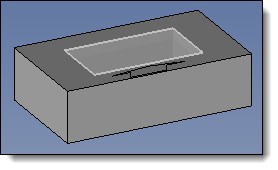

Go back to the method’s generic

document. From the Sketches

folder of the entities tree, right-click on the yellow sketch

and select the Sketch >

Others > Basify command. Open the method document and

observe that this sketch is no longer present in the operations

folder. Save the method document. Apply this method again in

an assembly and notice that the yellow sketch is no longer

created. |

![]()