nests the parts enclosing box

of one identical part per support, with a horizontal

and vertical security gap, defined

in the Parts tab.

nests the parts enclosing box

of one identical part per support, with a horizontal

and vertical security gap, defined

in the Parts tab.

|

Cluster Nesting |

The Cluster nesting  nests the parts enclosing box

of one identical part per support, with a horizontal

and vertical security gap, defined

in the Parts tab.

nests the parts enclosing box

of one identical part per support, with a horizontal

and vertical security gap, defined

in the Parts tab.

|

Cluster nesting places only one type of part on the same support. |

Available options:

Cluster nesting: This mode allows to place the parts, following the packing and the chosen ordering:

Packing:

On the bottom left: The

placement is done by starting at the bottom left of the support, the loss is

at the top right.

On the bottom left: The

placement is done by starting at the bottom left of the support, the loss is

at the top right.

On the top left: The placement is done

by starting at the top left

of the support, the loss is at the bottom

right.

On the top left: The placement is done

by starting at the top left

of the support, the loss is at the bottom

right.

On the top right: The

placement is done by starting at the top

right of the support, the loss is at the bottom

left.

On the top right: The

placement is done by starting at the top

right of the support, the loss is at the bottom

left.

On the bottom left: The

placement is done by starting at the bottom

right of the support, the loss is at the top

left.

On the bottom left: The

placement is done by starting at the bottom

right of the support, the loss is at the top

left.

Ordering: allows to determine the disposition of the parts.

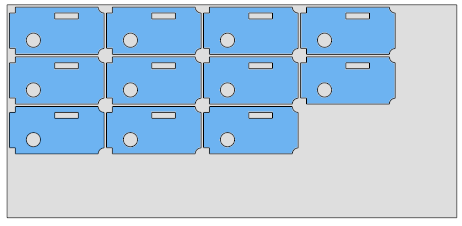

Horizontal

then horizontal: The parts are placed horizontally

with the start of each line on the same side. This means that

the first parts of each line will be on top of each other.

Horizontal

then horizontal: The parts are placed horizontally

with the start of each line on the same side. This means that

the first parts of each line will be on top of each other.

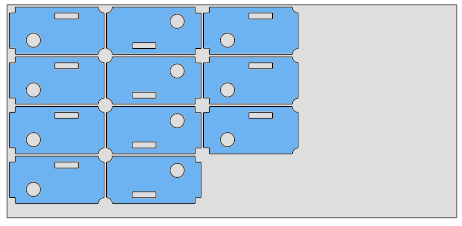

Horizontal

then vertical: The parts are placed horizontally, alternating

the start of each line. This means that the first part of

each line will be above the last part of the previous line.

Horizontal

then vertical: The parts are placed horizontally, alternating

the start of each line. This means that the first part of

each line will be above the last part of the previous line.

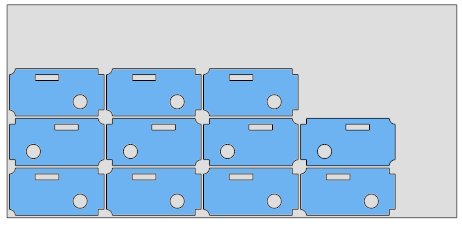

Vertical then

vertical: The parts are placed vertically with the

start of each line on the same side. This means that the first

parts of each line will be next to each other.

Vertical then

vertical: The parts are placed vertically with the

start of each line on the same side. This means that the first

parts of each line will be next to each other.

Vertical then

horizontal: The parts are placed vertically, alternating

the start of each line. That is to say that the first part

of each line will be next to the last part of the previous

line.

Vertical then

horizontal: The parts are placed vertically, alternating

the start of each line. That is to say that the first part

of each line will be next to the last part of the previous

line.

180 degrees rotation alternated by row: allows you to alternate the positioning of the parts by turning the parts 180° (around the Z axis of the part frame) between each row.

Flips: If flipping has been allowed on the part, it is possible to flip it.

Horizontal: the flips are made around the X axis of the support.

Vertical: the flips are made around the Y axis of the support.

Alternated: the flip is done every other row. Otherwise, all the parts are flipped.

Examples:

|

|

|

|

|

|

|

|