|

|

Serialization Parameters Example |

The example below shows how to use the serialization parameters (index, primary index, multiplier index).

Let's take the example of a part (plate) that should be included and repeated in an assembly. Each part must be identified as well.

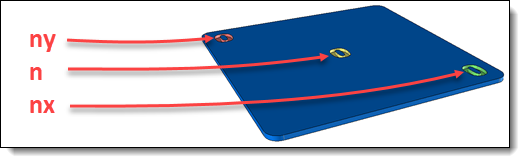

In the generic document of the part, the n, nx and ny parameters have been created, they will be redirected on the serialization parameter during the inclusion of the part in the assembly.

The value of these parameters has been set to zero and the corresponding texts are used for creating pockets on the part shape.

The parameter named n is also used for modifying the part thickness.

Then, these parameters are defined as drivers in the Family document.

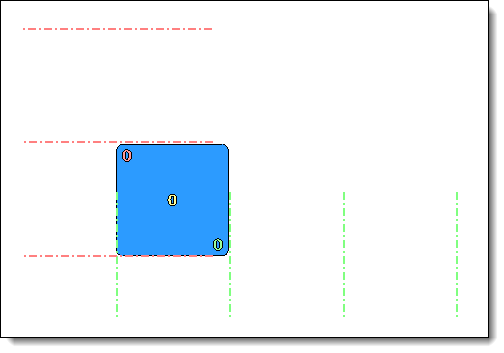

In an assembly document, the serialization index, the serialization primary index and the serialization multiplier index have been created.

The axes allowing to position the part have been also created and repeated along the X and Y directions.

During the inclusion of the part's family, the n, nx and ny parameters are matched with the serialization index parameters:

n : serialization index

nx : serialization primary index

ny : serialization multiplier index

The part is positioned using the original axes of each repetition.

A serialization operation is created using the part's occurrence and the 3 serialization parameters and choosing the repetition along X as driver and the repetition along Y as multiplier driver.

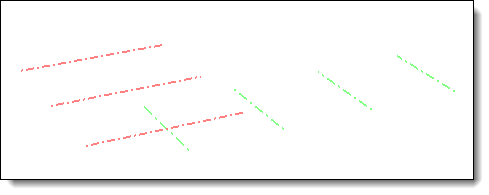

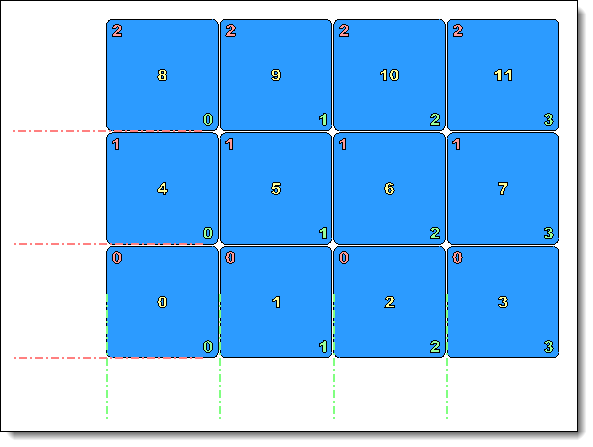

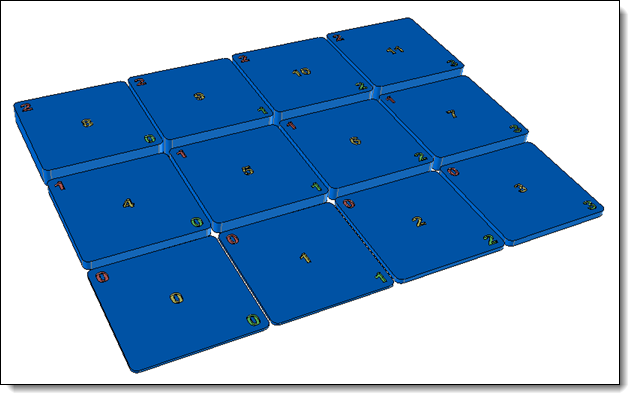

Then we get the following result:

|

For each part:

At the top left: the serialization multiplier index.

In the middle: the serialization index

At the bottom right: the serialization primary index |

|

|

|

|

The thickness of the generic part depends on the n parameter and the n parameter depends on the serialization index. So the thickness of each part is different. |