|

Manual:

interruption profiles will be created manually. Manual:

interruption profiles will be created manually.

Select the direction If necessary, select a measure point

on the view. With non parallel interrupt profiles this point

allows to define between which points to compute the offset

(see image below). The next step allows you to draw

the interruption sketch. The next step allows you to give

the offset value (spacing between interruption profiles) and

to modify their attributes.

|

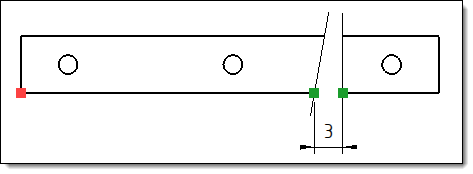

Example

of the use of an axis measure point (red point). The offset

of 3mm entered by the user is calculated between the green

points, resulting from the intersection with an axis passing

through the measuring point. |

Manual

Standard: interruption profiles are selected from a

list of predefined types. Manual

Standard: interruption profiles are selected from a

list of predefined types.

Select the direction. Edit

existing interruption: when the selected view has already

been interrupted, it is possible to activate this option in

order to complete the existing interruption instead of creating

a second interruption operation. This option will remain grayed

out if the selected view contains several interruptions made

separately. Select a type of predefined interruption

profile (line, wave, zigzag or small zigzag). Enter the offset value (spacing between

profiles defining an interruption). Modify the attributes of the interruption

profiles if necessary. Position the profiles on the view

(you can place as many as you need). Validate.

Automatic

Standard: this mode allows to automatically interrupt

a view, taking into account the topology of the part. Automatic

Standard: this mode allows to automatically interrupt

a view, taking into account the topology of the part.

Select the direction. Select a type of predefined interruption

profile (line, wave, zigzag or small zigzag). Enter the offset value (spacing between

profiles defining an interruption). Minimal length: only shapes

that are longer than the minimum length will be interrupted. Mode:

Minimum

size of interrupted area: only areas whose size is greater

than n% of the total length will be interrupted.

|

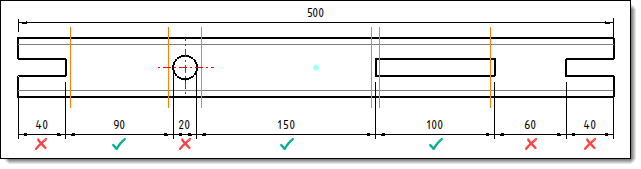

Example

of an automatic interruption in the minimum

size mode of the interrupted area mode of 15%.

Only

areas larger than 75mm (15% of 500mm) will be interrupted. |

Sum

of interruptions: TopSolid interrupts the areas as long

as n% of the total length is less than the sum of the interruptions.

The areas to be interrupted are considered in descending order

(from the largest to the smallest).

|

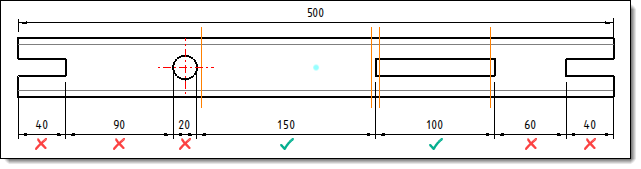

Example

of automatic interruption in sum

of interruptions mode of 65%.

Only

areas whose sum is less than 325mm (65% of 500mm) will

be interrupted.

Areas

of 150mm and 100mm are interrupted because: 150mm + 100mm

= 250mm < 325mm.

The

90mm area is not interrupted because: 150mm + 100mm +

90mm = 340mm > 325mm. |

Shrinkage factor: this option

allows you to shift the profiles of the geometry. Necessary

to avoid overlapping profiles when two areas to be interrupted

follow each other. TopSolid averages the interruptions found

(whether possible or not), applies the factor to this average

and shifts the profiles with the result. If a shrinkage factor

of 10% is set in the above example, the interruption profiles

will be shifted by 7.14mm (10% of (500mm / 7 interruptions)). Modify the attributes

of the interruption profiles if necessary. Validate.

|

Operations

at the ends of the shape will not be interrupted if they

are contained in an area less than 20% of the total length

of the shape.

They are still used in the calculation of the areas

to be interrupted (especially in the Sum

of Interruptions mode).

|

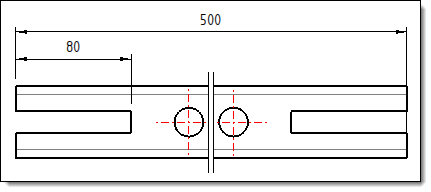

Example of an

automatic interruption in the Minimum

size of interrupted area of 15%.

Although the 80mm

operation is greater than 15% of the total length

of 500mm it is not interrupted because it remains

less than 20% of the total length. |

|

|

icon or select

the View > Interrupted

view... command from the drop-down menu.

icon or select

the View > Interrupted

view... command from the drop-down menu.